Advanced EOT Crane Solutions for Next-Generation Industries

Introduction

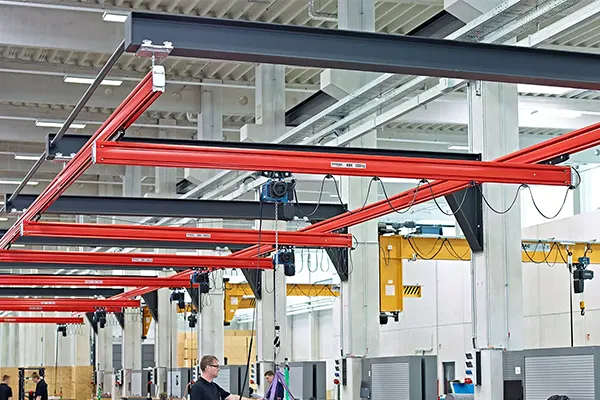

In today’s fast-evolving industrial landscape, lifting solutions must do more than carry weight — they must deliver precision, safety, energy efficiency, and smart automation.

Electric Overhead Travelling (EOT) Cranes have transformed from mechanical lifting tools into intelligent, sensor-driven systems managing complex operations across sectors such as steel, wind energy, heavy fabrication, and infrastructure.

At K2 Cranes, we believe that “All Things Bright and Beautiful” stem from engineering excellence. Every lift we design combines structural strength, intelligent control, and purposeful innovation.

K2’s EOT cranes incorporate cutting-edge technologies — from Variable Frequency Drives (VFDs) and smart sensor networks to intelligent control systems — setting new standards for performance, safety, and reliability.

Key Technological Features of K2 Cranes’ EOT Systems

1. Multi-Motion Variable Frequency Drive (VFD) Integration

- Each crane motion — hoisting, cross-travel, and long-travel — is controlled through dedicated VFDs, offering:

- Micro-Speed Precision: Operate at <5% of rated speed for high-accuracy positioning.

- Smooth Acceleration/Deceleration: Minimizes load swings and mechanical stress.

- Energy Efficiency: Features like dynamic braking and energy regeneration reduce power consumption.

- Extended Equipment Life: Reduced wear on motors, gearboxes, and brakes enhances system longevity.

At K2, we ensure that “The Journey is as Important as the Destination” — every motion is engineered for seamless control and optimal performance.

2. Advanced Sensor Networks

Our cranes are equipped with high-precision sensors that enhance safety and productivity:

- Load Monitoring: Prevents overload conditions in real-time.

- Anti-Collision Systems: Laser/ultrasonic sensors prevent crane interference.

- Positioning Sensors: Enable pinpoint trolley placement and zoning.

- Temperature & Vibration Monitoring: For predictive maintenance of motors and bearings.

These smart systems protect assets, reduce downtime, and ensure safe operations.

3. Intelligent Control Systems

Using PLCs and HMIs, K2 cranes are built for multitasking in dynamic environments:

- Automated Load Cycles: Ideal for repetitive operations.

- Multi-Hook Synchronization: Safely lifts large or uneven loads.

- Remote Monitoring & Diagnostics: Access performance data and alerts in real time.

- At K2 Cranes, we help industries move “Onwards and Upwards” — through automation and intelligence.

4. High-Precision Drives & Communication

- CAN Bus / Industrial Ethernet: Enables fast, secure communication between systems.

- Closed-Loop Feedback: Constant adjustments for speed, torque, and accuracy ensure optimal performance.

These systems lay the foundation for coordinated, flawless operations.

5. Industry 4.0 & Automation Readiness

K2 EOT cranes are fully ready for digital integration:

- IoT Connectivity: Real-time data via cloud for remote access.

- Remote Troubleshooting & Software Updates: Minimize service disruptions.

- Predictive Maintenance Analytics: Reduce unplanned downtime, improve lifecycle efficiency.

We engineer cranes not just for today — but for tomorrow’s smart factories.

Applications Across Key Industries

K2 Cranes intelligent lifting solutions serve diverse industries:

- Automotive Assembly & Body Shops

- Wind Energy (blade & nacelle handling)

- Railway

- Marine – Shipbuilding & Port Operations

- Aerospace

- Steel & Coil Management

- Heavy Fabrication & Modular Construction

- FMCG

- Pharma

- Granites

- Infrastructure

- Appliances

Conclusion

At K2 Cranes, we build more than machines — we engineer integrated lifting systems that deliver reliability, intelligence, and sustainability.

Our EOT cranes are crafted to support your production goals today and evolve with your future.

All Things Bright and Beautiful.

The Journey is as Important as the Destination.

Onwards and Upwards.

K2 Cranes | Engineering Excellence in Motion