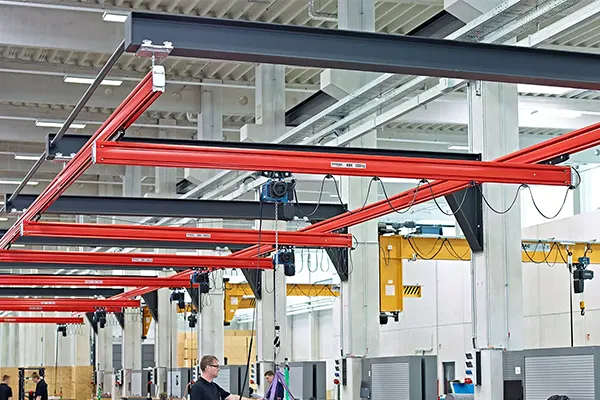

K2 EOT Crane offers electrically operated Single Girder wire rope hoists. These hoists are manufactured at K2’s modern manufacturing facility and offer customers the best in technology. Capacity for hoists range from 500 kg – 100 Tons and can be offered in single speed / dual speed design. Where space is a constraint hoist of Low Head Room type (LHR) can be offered to meet specific customer’s requirement.

The hoist gear boxes are 3 stage helical gear box and the hoist motor is with IP 54 / 55 enclosures. The standard design incorporates DC Electro Magnet Disc brakes and the hoists come fitted with protective rope guide. Overload protection by means of limit switches and other electrical means is offered.

Besides the standard speed, faster lifting speeds can also be considered for specific customer applications. The open design for hoists component assures customers the ease of maintenance and easy accessibility to all hoist parts (refer figure above). The cross travel trolleys are so designed to accommodate available sizes of mono rails or standard I beams. These hoists are also suitable for fitting onto under-slung cranes.

All electrical components are of reputed make and are easily available for replacement. The main operating voltages are 3 phase, 415 volts and 50 HZ.