Precision Engineering in Motion: Inside K2 Cranes’ Advanced Manufacturing Facility

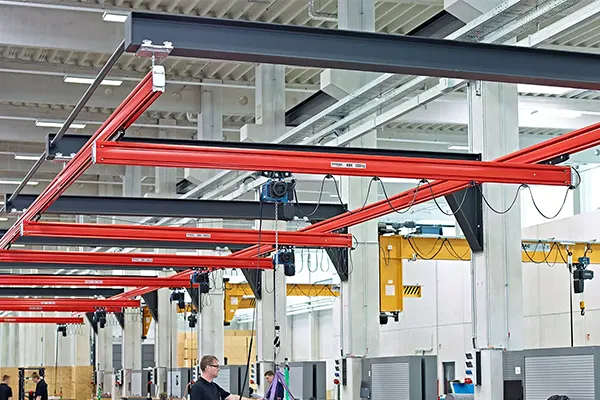

In the realm of industrial lifting solutions, precision engineering stands as a cornerstone of innovation and reliability. At the heart of this advancement is K2 Cranes, a leading name in the manufacturing of EOT cranes and overhead crane systems. Their state-of-the-art manufacturing facility exemplifies the fusion of technology and craftsmanship, setting new benchmarks in the crane manufacturing industry.

The Pinnacle of Crane Manufacturing Excellence

K2 Cranes’ manufacturing facility is a testament to their commitment to quality and innovation. Equipped with cutting-edge machinery and a skilled workforce, the facility specializes in producing a wide range of industrial cranes, including gantry cranes, jib cranes, and customized lifting solutions. This dedication to excellence ensures that each product not only meets but exceeds industry standards.

Embracing Advanced CNC Machining

Central to K2 Cranes’ manufacturing prowess is the integration of CNC machining technology. This allows for the production of components with unparalleled precision, ensuring optimal performance and longevity. The use of CNC machining in crafting crane components like gears, shafts, and hoist drums underscores the company’s focus on delivering high-quality, reliable products.

Commitment to Quality and Safety

Quality control is paramount at K2 Cranes. The facility adheres to stringent quality assurance protocols, ensuring that every crane component undergoes rigorous testing and inspection. This meticulous approach guarantees that the final products are not only efficient but also safe, aligning with the company’s ethos of prioritizing safety in all operations.

Sustainable Manufacturing Practices

In today’s environmentally conscious world, K2 Cranes leads by example through its sustainable manufacturing practices. The facility incorporates energy-efficient processes and waste reduction strategies, reflecting the company’s commitment to environmental stewardship. This approach not only benefits the planet but also resonates with clients seeking eco-friendly industrial solutions.

Tailored Solutions for Diverse Industries

Understanding that different industries have unique lifting requirements, K2 Cranes offers customized crane solutions tailored to specific operational needs. Whether it’s the automotive sector, construction, or heavy engineering, the company’s ability to provide bespoke solutions sets it apart in the competitive landscape of crane manufacturers.

Strategic Location and Global Reach

Situated in a strategic location, K2 Cranes’ manufacturing facility benefits from excellent logistics and supply chain networks. This enables the company to efficiently serve a diverse clientele, both domestically and internationally. Their global reach is a testament to the trust and reliability they’ve built over the years.

Investing in Human Capital

Beyond technology and machinery, K2 Cranes recognizes the value of its workforce. Continuous training and development programs ensure that employees are well-versed in the latest manufacturing techniques and safety protocols. This investment in human capital translates to superior product quality and customer satisfaction.

Future-Ready Manufacturing

As the industry evolves, K2 Cranes remains at the forefront by embracing smart manufacturing and Industry 4.0 principles. The facility is geared towards integrating IoT-enabled devices and real-time monitoring systems, paving the way for predictive maintenance and enhanced operational efficiency.

Conclusion

K2 Cranes’ advanced manufacturing facility is more than just a production site; it’s a hub of innovation, precision, and excellence. By combining state-of-the-art technology with a skilled workforce and sustainable practices, the company continues to redefine standards in the crane manufacturing industry. For businesses seeking reliable and customized lifting solutions, K2 Cranes stands as a beacon of quality and innovation.