Safety First: Essential Crane Safety Practices for Industrial Operations

Safety First: Essential Crane Safety Practices for Industrial Operations

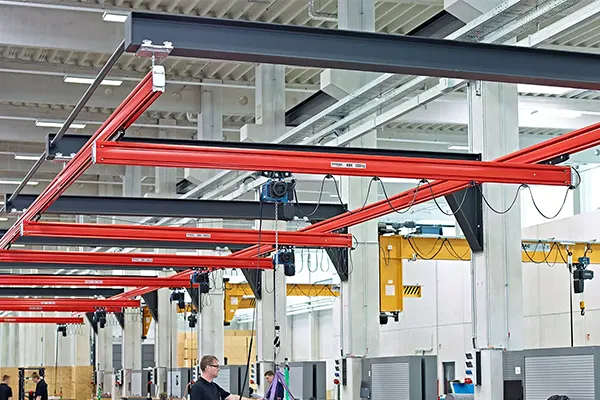

In any industrial environment, safety is not just a guideline—it’s a necessity. Cranes are indispensable for lifting and moving heavy loads, but without proper safety practices, they can also become serious hazards. Whether it’s a factory floor, construction site, or logistics hub, ensuring crane safety is crucial for protecting both people and property. By following structured protocols and investing in the right training and technology, industries can minimize risks and maximize productivity.

Why Crane Safety Matters

Cranes are powerful machines, capable of lifting multiple tons of materials. However, a single oversight—like an unbalanced load or a distracted operator—can lead to dangerous incidents such as equipment failure, dropped loads, or even fatalities. According to industry reports, a significant percentage of workplace accidents involve improper crane usage or maintenance.

The good news? Most crane-related accidents are preventable with the implementation of essential crane safety practices.

1. Regular Inspection and Maintenance

One of the most effective ways to ensure crane safety is through routine inspection and preventive maintenance. Cranes, like any mechanical equipment, undergo wear and tear. Without timely checks, critical issues can go unnoticed.

Key components to inspect include:

- Wire ropes and chains for fraying or corrosion

- Brakes and limit switches for responsiveness

- Hooks and load blocks for cracks or deformation

- Control systems and panels for proper functionality

Scheduling daily visual checks, along with monthly and annual certified inspections, ensures that the crane is always in safe working condition.

2. Operator Training and Certification

Cranes should only be operated by trained and certified professionals. Operators must understand:

- Load capacity limits

- Safe lifting techniques

- Emergency procedures

- Proper signaling and communication

Training should also include understanding of the specific type of crane being used—such as EOT cranes, gantry cranes, or jib cranes—since each comes with unique operating procedures. Regular refresher courses keep operators up-to-date with evolving safety standards and technologies.

3. Understanding Load Capacity and Weight Limits

One of the most common causes of crane accidents is overloading. Every crane has a safe working load (SWL), which must never be exceeded. Operators and ground personnel should be trained to:

- Calculate and verify the weight of the load

- Use load indicators and limiters correctly

- Balance the load to prevent swinging or tilting

Using load testing equipment and overload protection devices can further reduce the risk of over-capacity lifts.

4. Clear Communication and Signaling

In noisy industrial environments, verbal commands alone are insufficient. That’s why standardized hand signals and radio communication are critical for smooth crane operation. There should always be a designated signal person who communicates with the crane operator to guide lifts, ensuring that movements are controlled and predictable.

For more advanced safety, companies can also implement remote control systems or camera-assisted monitoring to improve visibility and coordination.

5. Proper Ground Preparation and Surrounding Awareness

The area around the crane should be clear of obstructions, debris, and unauthorized personnel. Ground conditions must be stable, especially for mobile or gantry cranes. Operators should be aware of:

- Overhead obstructions like power lines

- Nearby workers and machinery

- Weather conditions (e.g., strong winds can affect crane balance)

Creating safety zones and marking hazard areas with barriers and signs are essential to maintaining a secure operation site.

6. Emergency Preparedness and Shutdown Protocols

Even with precautions, emergencies can still occur. That’s why having a clearly defined emergency response plan is vital. Operators and workers should be trained on:

- How to initiate emergency stops

- Evacuation routes and procedures

- First aid and incident reporting

Modern cranes often come equipped with emergency stop buttons, automatic brakes, and backup power systems to minimize the impact of sudden failures.

7. Implementing Safety Technologies

The evolution of smart manufacturing has introduced advanced safety tools in cranes, such as:

- Anti-collision systems to avoid crashes

- Overload sensors and alarms

- Automated diagnostics and real-time monitoring

- IoT-enabled maintenance alerts

K2 Cranes, a leading crane manufacturer in India, is a pioneer in integrating such safety features into their cranes. Their approach ensures that their EOT cranes and other models meet not just performance expectations, but the highest safety standards.

Final Thoughts

Crane operations are at the heart of industrial productivity, but they come with significant responsibilities. Prioritizing safety through regular maintenance, skilled operation, smart technologies, and workplace discipline can drastically reduce the risk of accidents.

By following these essential crane safety practices, industries not only protect their workforce and equipment but also build a culture of accountability and excellence. As the industry continues to evolve, safety will remain the foundation of efficient and responsible crane operations.