The Future of Heavy Lifting: How EOT Cranes Are Transforming the Construction Industry

The Future of Heavy Lifting: How EOT Cranes Are Transforming the Construction Industry

In an era of rapid industrialization and urban development, the demand for efficient, safe, and high-capacity lifting solutions has never been higher. Among the various technologies revolutionizing the construction industry, Electric Overhead Travelling (EOT) Cranes stand out as game changers. These powerful machines have redefined how construction companies handle heavy loads, streamline operations, and ensure workplace safety.

What Are EOT Cranes?

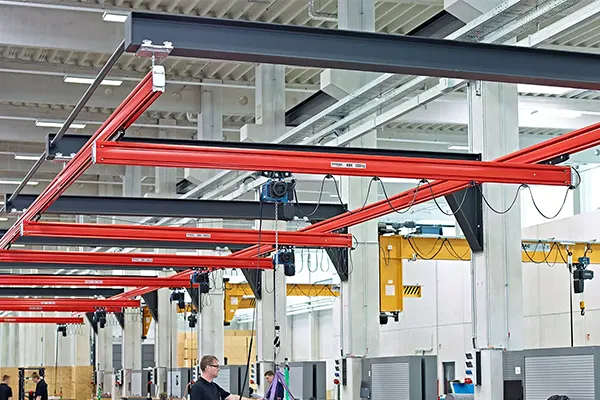

EOT cranes are electrically powered overhead cranes that move on elevated runways within a building or factory. They are primarily used to lift, lower, and move heavy materials across short distances. Commonly found in manufacturing units, warehouses, and large construction sites, EOT cranes come in two main types: single girder and double girder, each suited for different lifting capacities and applications.

Why EOT Cranes Are Crucial in Construction

Modern construction projects involve massive structures, complex machinery, and tight deadlines. Traditional manual handling or even basic lifting equipment falls short when it comes to heavy components like steel beams, precast slabs, or machinery parts. EOT cranes fill this gap by offering:

- Higher Load Capacity: They can handle loads ranging from a few tons to over 300 tons, making them suitable for diverse lifting needs.

- Operational Efficiency: They significantly reduce manual labor, increase speed, and allow for precise positioning of materials.

- Enhanced Safety: With advanced control systems and minimal human intervention, EOT cranes help lower the risk of workplace accidents.

The Role of Companies Like K2 Cranes

K2 Cranes, one of South India’s leading EOT crane manufacturers, is at the forefront of this transformation. Since 2008, the company has played a critical role in supplying high-quality cranes to various sectors, including construction, automotive, steel, and infrastructure. With a robust manufacturing facility capable of producing cranes up to 300 tons, K2 Cranes has become synonymous with reliability and innovation.

Their cranes are equipped with the latest features such as variable frequency drives (VFDs), anti-collision systems, remote control operations, and ergonomic operator cabins, ensuring that customers benefit from both performance and safety.

EOT Cranes in Mega Projects

The use of EOT cranes in large-scale infrastructure projects is growing rapidly. From high-rise buildings to industrial plants and railway infrastructure, these cranes have become essential. A recent example is K2 Cranes’ involvement in the Mumbai-Ahmedabad Bullet Train project. The company supplied specialized cranes tailored for the unique requirements of this high-speed rail project, demonstrating the versatility and scalability of EOT crane technology.

Sustainability and Efficiency

As sustainability becomes a priority across industries, EOT cranes offer a more energy-efficient solution compared to older lifting equipment. With reduced power consumption, regenerative braking systems, and lightweight designs, they contribute to lower carbon footprints and operational costs.

Companies like K2 Cranes are also focusing on building energy-efficient cranes that support green building initiatives and smart construction practices.

Digital Transformation and Smart Cranes

One of the most exciting developments in the EOT crane industry is the integration of smart technologies. Today’s cranes are not just mechanical lifting devices—they are intelligent systems capable of real-time data collection, condition monitoring, and predictive maintenance.

By integrating IoT (Internet of Things), AI (Artificial Intelligence), and automation, companies can track crane performance, predict potential failures, and ensure timely maintenance—all of which minimize downtime and maximize productivity.

K2 Cranes, with its forward-looking R&D approach, is already exploring these areas to bring cutting-edge solutions to its clients.

The Future Outlook

The global EOT crane market is poised for significant growth, fueled by the expanding construction, logistics, and manufacturing sectors. As more industries prioritize automation and safety, the demand for customized and smart lifting solutions will increase.

For construction companies, investing in advanced EOT cranes is not just about handling heavy materials—it’s about staying competitive, meeting project deadlines, and ensuring worker safety. With manufacturers like K2 Cranes leading the innovation wave, the future of heavy lifting looks stronger and smarter than ever.

Conclusion

EOT cranes are transforming the construction industry by offering unmatched lifting capacity, improved safety, and operational efficiency. As technology continues to evolve, these cranes will become even more intelligent, eco-friendly, and indispensable. Whether it’s a towering skyscraper or a high-speed railway, EOT cranes are lifting the world—one project at a time.